Content

When walk-behind tractor for household needs it becomes little, a person is thinking about purchasing a mini-tractor. But the cost of such equipment starts from 100 thousand rubles and not everyone can afford it. This is where the question arises of how to make a mini-tractor with your own hands at minimal cost.

Preparation of drawings

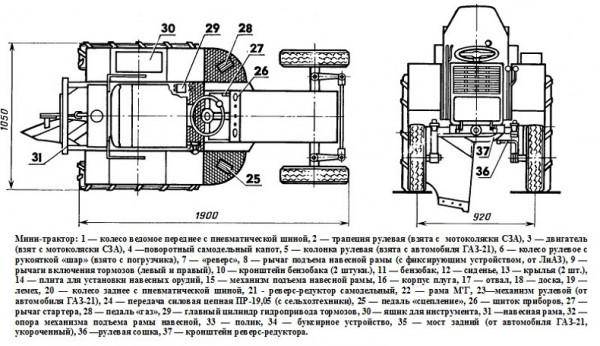

Owners make such homemade products from old parts from a car or remake a walk-behind tractor. There are many options, and each design is individual. In any case, if you are going to fold the mini-tractor, then you cannot do without a drawing. On the diagram, be sure to indicate the dimensions of the frame, the location of all nodes and other details. In the photo we propose to see what the mini-tractor consists of. You can build on this scheme when developing a drawing.

The frame is the foundation of the structure. It is on it that all the units of the mini-tractor are attached. Today we will consider homemade a mini-tractor on a one-piece frame, so in the photo we suggest looking at its drawing with the dimensions of the units.

Drawing up a drawing is a mandatory step, since the process of assembling a mini-tractor requires fitting all parts taken from other equipment. It is impossible to remember all the nodes, but according to the scheme you will always be guided and go in the right direction. In addition, turning work may be required. By looking at the drawing, the turner will already be able to have an idea of what you want from him.

Assembling a mini-tractor from old car parts

So, we figured out the importance of the drawing, and we will assume that you have already drawn it. Now you need to prepare the main parts. These include: engine, steering and transmission. For the manufacture of the frame, you will need a channel or a profile pipe.

We make the frame

For a homemade mini-tractor, you can make two types of frames:

- The broken frame consists of two separate rectangular structures. That is, two semi-frames are welded. They are connected to each other by a special mechanism - a hinge. A structure is made from channel No. 5 or No. 9. In such a mini-tractor, a steering column is placed at the joint of two elements, and the front wheels are turned together with a semi-frame.

- The one-piece frame is a welded structure with two side members and a rear and front cross member. Channel No. 10 and No. 12 are suitable for their manufacture, respectively. To stiffen the structure, a jumper from a profile pipe is welded across the frame. On a one-piece frame, the steering column will only steer the front axle with wheels.

Of the two options considered, a one-piece frame is easier to make for a mini-tractor with your own hands, so it's worth stopping at it.

Engine and transmission

The choice of motors for a homemade mini-tractor is not large. Weak engines must be discarded immediately, even if you can get them for free. After all, you do not need an unproductive tractor. Optimally for such homemade products, UD-2 or UD-4 motors are suitable. They are characterized by economical fuel consumption and good performance. One- or two-cylinder diesels may also work. It is more difficult to get the M-67 motor. If you managed to do this, then the long-term operation of the mini-tractor is guaranteed. In addition, this brand of engine is cheap to maintain.

Before installing on the frame, the motor needs to be improved. First, the gear ratio is increased first. Secondly, you will have to make an air cooling system yourself. For this, a fan is connected to the crankshaft.A hanging casing is installed around the blades. It will direct the cool air flow to the motor.

When assembling units from parts of different brands of cars, you will have to make adjustments. Let's say the gearbox and PTO are taken from the GAZ-53, and the clutch is from the GAZ-52. To fit them, a new clutch basket is welded. On the flywheel of the motor, the plane of the rear is reduced, and a new hole is drilled in the center.

Steering selection

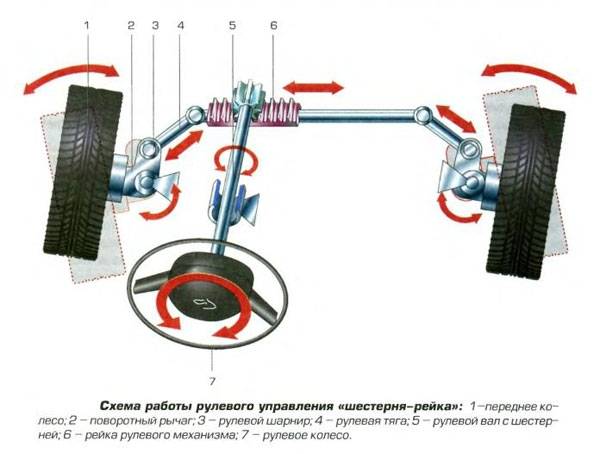

It is impossible to make the steering control yourself. It will have to be removed from the old equipment. The simplest option is a worm gear. The steering column will fit any passenger car. On a one-piece frame, the front axle with wheels is pivoting, therefore it is connected with rods to the column. On a broken frame, a gear is welded to the front half. Exactly such a part is attached to the steering column. The rotation of the front half-frame will be carried out due to the clutch of two gears.

For better controllability, a homemade mini-tractor can be equipped with a unit with hydraulic cylinders. But to circulate the oil, you will have to install an additional pump. Such a steering cannot be assembled on your own. It can only be completely removed from agricultural equipment.

Axles and wheels

The rear axle of the mini-tractor is the driving one. It is better to take it from an old passenger car. You may need to contact a turner to reduce the axle shafts. The front axle is not driving. This unit can be made from a piece of pipe by fitting bearings onto the ends or similarly removed from old equipment.

The size of the wheels is chosen depending on what the homemade mini-tractor will do. For cargo transportation and other similar work, 16-inch rims with tires are suitable. But most often a mini-tractor is assembled precisely for soil cultivation, planting and harvesting. In this case, optimum grip of the tires with the ground is important. Only 18- or 24-inch wheels can provide such parameters.

The assembled mini-tractor is first run in without load. If the tests are successful, the machine can be taken out into the field.

If you are interested in the option of a mini-tractor with a broken frame, watch the video presented:

Converting a walk-behind tractor into a mini-tractor

If you have a walk-behind tractor at home, it will be even easier to fold a homemade mini-tractor with your own hands, since the motor and front wheels are already unnecessary to look for. Especially for such alterations, kits are sold, consisting of all the necessary spare parts. To make it cheaper, you can follow the same path as discussed above. You will have to remove the necessary nodes from the old equipment.

The alteration process of different brands of motoblocks differs due to their design features. Here you need to find an individual solution. But, in general, the principle of making a homemade mini-tractor is similar to the previous version:

- First, the frame is welded. It can be solid or articulated.

- It is important to correctly assemble the undercarriage and determine the optimum track gauge. It all depends on the location of the motor. If it is installed on the front of the frame, then the track width remains native. That is, the front wheels of the walk-behind tractor are used. The rear axle is made from a steel bar or a piece of pipe. It is fixed to the frame, and bushings with bearings for the wheels are pressed onto the ends.

- With the rear engine on the frame, the native track width of the walk-behind tractor is expanded. This action is mandatory, as it is necessary to achieve the stability of the mini-tractor.For better grip with the ground, you need to make lugs for a homemade tractor.

- The steering will come out even from the native handles. Often this is practiced when remaking an MTZ walk-behind tractor. A mini-tractor is made three-wheeled, where a motorcycle wheel turns with its own handles. However, this option is inconvenient for reversing. It is optimal, after all, to stop at the steering column of a passenger car. The driver's seat is attached to the frame with racks. They should be adjustable in height and tilt so that it is convenient for a person to work.

The finished mini-tractor still needs to be run in and then given a load.

The video shows an example of a converted Neva walk-behind tractor into a mini-tractor:

It is difficult to assemble a mini-tractor for the first time. There will definitely be some imperfections in the design. They can be corrected after identifying in the process of using the technique.