Content

Many domestic cow owners managed to try the milking machine Burenka. There were a lot of reviews about the equipment. Some people like it, other owners are not happy. The range of milking machines produced under the Burenka brand is large. The manufacturer offers dry and oil-type units designed for milking a certain number of livestock.

Advantages and disadvantages of milking machines for cows Burenka

In general terms, Burenka's equipment has the following advantages:

- high quality hoses and elastic liners;

- capacious stainless steel container;

- piston models are not afraid of milk entering the piston;

- high-quality shipping container.

The disadvantages include:

- heavy equipment;

- there is no place for winding the network wire;

- the presence of a large number of moving units creates a loud sound during operation;

- sometimes unstable milking is observed.

There are a lot of negative reviews from the owners about the Burenka milking machine, and most of them concern piston models. Livestock breeders complain about too loud work. Inside the engine, you can clearly hear the tapping characteristic of the operation of the crankshaft with pistons.

Long-term working pressure build-up is considered a problem for many. From the moment of switching on, it should take from 30 to 60 seconds. Problems were observed when measuring ripple. Instead of the recommended frequency of 60 cycles / min. the equipment produces up to 76 cycles / min. In the passport data, the parameter of the ripple ratio is 60:40. However, the pump acts as a pulsator at the Burenka piston unit. The pistons move without delay, which gives the right to assume a real pulsation ratio of 50:50.

During operation, the third milking cycle - rest - does not work well for some models. The liner does not fully open and the cow feels uncomfortable. Milk is sometimes not fully expressed.

The lineup

Conventionally, Burenka aggregates can be divided into three groups:

- Dry models for milking 5 cows. The milking machines are equipped with a 0.75 kW motor with a rotation speed of 3 thousand rpm.

- Dry models for milking 10 cows. The devices are equipped with a 0.55 kW motor with a rotation speed of 1.5 thousand rpm.

- Oil-type models for milking 10 cows. The milking machines use a 0.75 kW motor with a rotation speed of 3 thousand rpm.

Each group includes a model with specific characteristics. The classification of devices is indicated by the abbreviation "Combi", "Standard", "Euro".

For home use, Burenka-1 devices of the basic configuration with the designation "Standard" are suitable. The milking machine can serve up to 8 cows. The device Burenka-1 with the abbreviation "Euro" has small dimensions. The equipment serves 7 cows per hour. The Burenka-1 N model is popular due to the presence of a dry vacuum pump that can function far from the teat cups.

The Burenka-2 model has improved characteristics. Two cows can be connected to the device at the same time. The milking machine serves up to 20 heads per hour.The dry type vacuum pump pumps 200 l of milk / min.

The milking machine Burenka 3m, equipped with an oil-type pump, has improved characteristics. The equipment is equipped with a 0.75 kW motor with a rotational speed of 3000 rpm. The model is designed for large farms. The general instructions for the Burenka 3m milking machine state that three cows can be connected for milking at the same time. The productivity is up to 30 cows per hour.

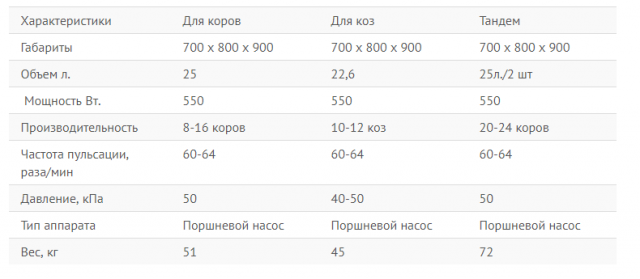

The characteristics of several models of the piston type for domestic use for milking goats and cows are shown in the table:

In the video, the work of the piston apparatus Burenka

Milking machine specifications

The Ukrainian manufacturer of milking machines Burenka has equipped its equipment with a stainless steel can, which has a better effect on the quality of milk. Milk hoses are made of transparent silicone, which improves the visual control of milking. Teat cups inserts Burenki are elastic, do not irritate teats and udders.

The following qualities are inherent in Burenka's devices:

- reliable work;

- capacious container for collecting milk;

- good performance;

- compactness of equipment.

Despite many negative reviews about piston units, other Burenka models have good characteristics and are easy to operate.

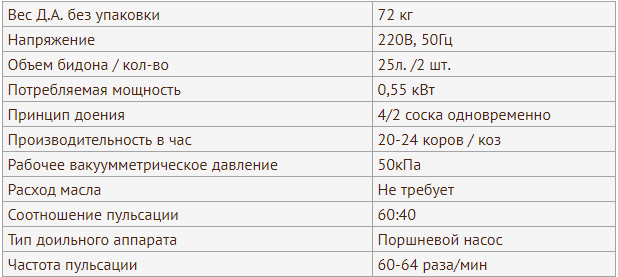

The table shows the characteristics of the milking machine Burenka "Tandem". The device is equipped with a convenient transport trolley. All items of equipment have free access. Compact dimensions, reliable wheelbase give the model maneuverability.

How to use the milking machine Burenka

The instruction attached to the Burenka milking machine mainly includes standard actions. The system is flushed before milking. Dry the glasses and milk collection container. If several cows are milked, washing is also required after each process. The teat cups are immersed in clean water, the motor is turned on. With the beginning of the creation of a vacuum, the apparatus will begin to suck the liquid through the teat cups, run it through the hoses, and drain it into the can. After drying, the silicone inserts of the teat cups are disinfected before use.

The udder is washed from dirt, adhered manure, wiped with a dry cloth. The nipples are especially carefully treated. They must fit completely dry into the teat cups. The udder of the cow is massaged well before milking.

A simple way of using the milking machine for Burenka cows allows a beginner breeder to quickly master the equipment:

- After washing and drying the apparatus, close the can lid. Open the vacuum tap and simultaneously activate the switch. The vacuum gauge should show an operating parameter of 36-40 mm Hg. If the value is not correct, perform an adjustment.

- Before connecting to the udder of the cow on the bundle of the teat cup connection, open the tap. Putting on each nipple is performed in turn. During the connection, do not rotate the glasses, otherwise the milking cycle will be disrupted, there will be irregular expression of milk.

- If the glasses are correctly connected to the udder, the milk will immediately flow through the hoses into the can at the beginning of milking. If mistakes were made, the system was depressurized, air hiss would be heard from the glasses. Milk may be missing if connected correctly if the cow is not ready for milking. The process is stopped immediately. The glasses are removed from the udder, an additional massage is performed, and the procedure is repeated.

- During the milking process, the operator controls the operation of the system. When milk stops flowing through the hoses, milking is stopped. The device must be turned off in time so as not to damage the udder of the animal. Milk from the can is poured into another container.

Experienced owners, after machine milking, check by hand pumping to see if the cow has given up all of the milk.Milking off small residues prevents udder mastitis.

General requirements include the rule of observing the start of milking time. The optimal period is two months from the date of calving. During this period, the calf is no longer given milk, but is transferred to vegetables, hay and other feed. In addition, by this time, milk is gaining its flavor value.

Conclusion

Milking machine Burenka will become a reliable assistant, will cope with its task, if you select it correctly according to the parameters. It is important to follow the manufacturer's recommendations in the equipment operating instructions.

the needle of the pressure gauge jumps does not hold a constant vacuum