Content

- 1 What is a honey extractor

- 2 Dimensions (edit)

- 3 What honey extractors are there

- 4 Electric honey extractor

- 5 Radial honey extractor

- 6 Wooden honey extractor

- 7 Chordial honey extractor

- 8 DIY honey extractor from a washing machine

- 9 DIY honey extractor from a plastic barrel

- 10 How to make a reversible two-cassette honey extractor with your own hands

- 11 Cassettes: buy or do it yourself

- 12 Do I need a stand

- 13 Work rules

- 14 Conclusion

The honey extractor was invented by the Czech F. Grushka in the middle of the 18th century. This was a completely new way of obtaining honeycomb, in which the healing nectar was completely pumped out, and the structure of the honeycomb was not destroyed. This device has fulfilled the long-held dream of all beekeepers and has reliably entered the beekeeping industry.

What is a honey extractor

The honey extractor is the most important item of the beekeeper's household equipment. If it is very primitive, then it is an empty cylindrical tank, with an internal system of rotating frames on a rigid axis. At the very beginning of its creation, it was exclusively wooden. It was made from wooden barrels or tubs, and the entire working moving mechanism was also made of wood.

Device and principle of operation

The fundamental principle of the honey extractor, created by F. Grushka, was so successful that it has practically not changed since its inception. Modern devices operate on the same principles for pumping honey, but have a more advanced, technological mechanism.

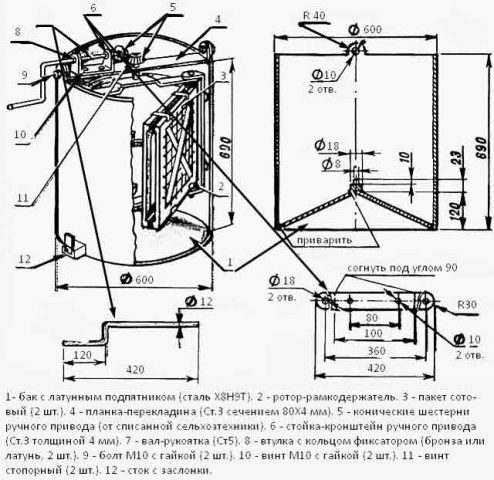

Description of the device using the example of a radial view.

The device is a metal tank with a curved conical bottom. Inside it, a metal cage is located on the vertical axis. The vertical axis rests on a cross, on which a "glass" is fixed, which has a steel ball at its base. The ball rests against a rod with a spherical bore. The rod has a screw connection with a vertical axis, which is a water pipe of 25 mm. At the top of the tank cone there is a metal tube 30 mm high. It prevents honey from dripping axially to the bottom of the honey extractor tank.

The steel cage of the device has upper and lower crosses. The bottom cross supports a thrust circle and two circles with slots (hinges) for frames. The top cross supports a stop circle at the top to secure the top edges of the bezels. The metal cage is positioned so that the lower part of the rotating frames does not touch the pumped out honey.

The upper part of the steel bar rotates in a ball bearing and has a conical gear at the end. The ball bearing is mounted in the plane of the plate, which is fixed to the cross member. The cross member is rigidly mounted on both sides of the metal tank. The movement of the honey extractor cage occurs through a vertical gear on the upper cross member, by rotating it manually (axles with a handle) or electrically by means of a belt or chain drive.

For the outlet of the pumped out honey, there is a special sleeve in the tank, which is located at the bottom of the structure at the very bottom. The sleeve is equipped with a secant valve and works to "open" and "close" the container with honey.

The top of the honey extractor tank has semicircular lids that are attached to a ball bearing plate. The covers are equipped with edges, they tightly and reliably cover the body of the device. For greater strength of the tank cover, the body itself has peripheral ridges. To prevent the semicircular lids from sliding off the tank during operation, they are attached to the gear with a special bracket.

The upper cross member with a rotating mechanism is fixed to the tank hoop with special curved bolts. The bolts hold the outer vertical strips, which are rigidly fastened to the lower tank hoop. This design firmly engages the top and bottom edges of the tank, preventing the structure from loosening during vibration.

The tank is installed on a cross (low table). The optimum lifting height of the body is 400-500 mm. For the convenience of receiving honey, the height of the legs of the cross is adjusted to the height of the container of the honey receiver (plastic or metal bucket, can, flask).

The principle of operation of the device is based on the centrifuge mechanism. The main working moment in it is the centrifugal force, which makes the viscous consistency of honey leave the honeycomb, melt and come out.

It happens in the following way. The frame with the honeycomb is printed out with a special beekeeper knife, and then installed in the cassette. Under the action of rotation, a centrifugal force appears in the frame, which pushes honey out of the honeycomb with high pressure. The released honey flows under its own gravity along the walls of the tank to the bottom of the honey extractor and flows out of the sleeve into the container by gravity.

Dimensions (edit)

The size and volume of the device directly depends on the number of hives on the farm and the size of the apiary itself. If we are talking about harvesting honey for our own consumption and the apiary of an amateur beekeeper is small, then a small apparatus for 4-6 frames is enough for the simultaneous pumping of honey. In this case, a low honey extractor with a diameter of 0.5-0.7 m with a manual or electric drive will be optimal.

For beekeepers who have this industry as a business, more powerful and larger electrical devices are needed with the simultaneous loading of up to 20 or more honeycomb frames.

What honey extractors are there

Industrial devices differ in shape, type and drive. Homemade and even more. Often, such honey extractors combine several types of rotor, are easy to transform, combine and work excellently.

Honey extractors are distinguished by several characteristics:

- by material of manufacture;

- by design (arrangement of cassettes);

- by the number of frames;

- by type of drive.

Before you start creating the design of the device, you should determine what material to make it from. This is an important point, since specific conditions are imposed on it - safety in contact with food, resistance to natural, mechanical stress, a high degree of wear in working with moving blocks (mechanisms).

The creation of a structure is possible from the following materials:

- Wood... Initially, honey extractors were made from this material. For this purpose, ready-made tanks, barrels or tubs were used.

- Stainless steel... This is the most popular material. It is practical, convenient and has a very large resource of use. That is why, to create a homemade honey extractor, the body of an old activator-type washing machine is often used.

- Aluminum, galvanized steel... Lightweight and lightweight materials, but strong enough for the task. Large thick-walled pots, kitchen pots, barrels or galvanized buckets are suitable for creating the apparatus.

- Food grade plastic... A modern, lightweight and inexpensive material that can also be used to create a honey extractor.However, to create it, you should select high-quality plastic containers for food use.

The design of the honey extractor has several types. It depends on the type of cassette arrangement in it. Devices are:

- radial;

- chordial;

- negotiable.

Amateur beekeepers use small devices with the number of frames from 3 to 6. Most often they use one frame honey extractors (made by hand), 2 frame stainless steel extractors and 3 frame rotary stainless steel honey extractors. This is justified by the small size of the apiary and the number of hives. It is not difficult to create such a structure from available means. For example, from an old but sturdy wooden or plywood barrel, from a disused washing machine.

Beekeepers on a large scale, for whom the industry has become their main source of income, use honey extractors with a simultaneous loading of 20 or more frames. This case speaks of the creation of a medium or large industrial beekeeping farm.

Drive type. A manual honey extractor is the most common type of device, since it does not require an attachment to an electrical outlet, is easy to use and safe. In addition, it is much easier to design a manual honey extractor using, for example, old bicycle chain sprockets.

Electric devices are driven by an electric drive with a motor and operate on a standard 220 V electrical network. As a rule, the electric drive is installed on bulky honey extractors with a large number of honeycomb frames for pumping out 30 kg of honey. Electric devices are more convenient for large beekeeping farms.

What are the turns in a honey extractor when pumping honey

Modern electric honey extractors can adjust the direction and speed of rotation, in addition, the electric drive provides a constant speed and has a dynamic braking function.

In honey extractors, electric drives are used with the following characteristics:

- pulse type;

- weight - 1.5-1.8 kg;

- voltage - from 10 to 14 V;

- speed sensor (electronic or induction);

- rotation speed - 30-150 rpm;

- rotation time - 1-10 minutes plus or minus 20%.

Large apiaries use portable batteries, small power plants, solar panels and conventional power grids during the honey processing season. In small beekeeping farms, to automate the work of the honey extractor, they use electric drills from a standard power outlet and mechanical drives with manual speed control.

Which honey extractor to choose

The main criteria for selecting a honey extractor are the consumer needs of the beekeeper himself or the beekeeping enterprise. When choosing a device, take into account:

- the size of the apiary;

- the number of hives;

- the number of pumping frames;

- the number of working hands for servicing the apparatus;

- availability of a suitable area with power supply;

- financial expenses.

When choosing a store-bought honey extractor, be sure to study the information about the manufacturer. It will not be useless to read the reviews of buyers of this technique, you can also ask questions of interest on the forums of beekeepers. Such curiosity will not be superfluous, but avoiding mistakes and unjustified expenses will definitely help.

Today, the most popular manufacturer of honey extractors is Plasma LLC. This company specializes in the production of beekeeping devices, is engaged in the design, manufacture and repair of various types of devices.

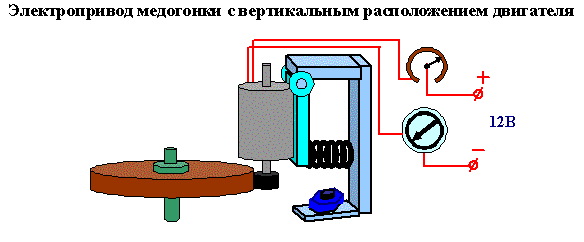

Electric honey extractor

Electric devices are used when pumping honey in large quantities in the conditions of honey production in large apiary areas. The electric drive is installed on chordial and radial devices.Privately, the electric drive can also be installed on combined or reversible homemade honey extractors.

The particular advantage of electric honey extractors is the saving of time and physical costs for processing beekeeping raw materials. The electric drive of the device makes it possible to change the direction of rotation of the drum, decrease or increase the rotation speed and time, which is an undoubted advantage in controlling the quality of honey pumping.

The principle of operation of an electric honey extractor is as follows. Honeycomb frames are unsealed with a special knife before loading into the tank. Further, the frames are inserted into the drum cassettes strictly according to the rules - opposite each other, taking into account the balancing of the weight. Before direct start-up, the rotor is rotated manually, and then the electric drive is activated. At first, the drum should rotate at low speed, after which the speed is increased. The maximum rotation time of a drum with frames is 25 minutes. After this time, the rotation speed is gradually reduced, and the movement is stopped altogether.

DIY electric honey extractor

A homemade electric honey extractor can be made from simple materials at hand. Any rotating power tool is suitable for this purpose, such as a drill, hammer drill or grinder. As a tank, you can use a container of a suitable size - a large bucket, a vat, a wooden tub, a plastic or galvanized barrel. Lattice shelves from an old refrigerator are perfect for creating cassettes. They need to be cleaned, rinsed, assembled into a standard cassette shape using steel wire and painted.

A hole should be made at the bottom of the tank to drain the honey. For the rack of the tank, a stable cross is made, which must have a rigid attachment to the frame. Now, when the device blank stands firmly "on its own feet", they proceed to creating the design of the cassette holder.

In the very middle of the bottom of the tank, a thrust bearing with a bearing is fixed, which will be the basis of the rotor axis from below. The frame of the frame holders must have the shape of a rectangle and have a steel tube-axis in the middle. Lattice cassettes made from refrigerator shelves are fixed to the frame. A cross member with a plate and a bearing is installed on top of the tank - this is the top of the rotor axis.

Next, an electric drive is fixed to the upper crossbar of the honey extractor (see the diagram above). As an electric drive, you can use a household electric drill, which is rigidly fixed to the tank body on special shelves with powerful bolts (photo below).

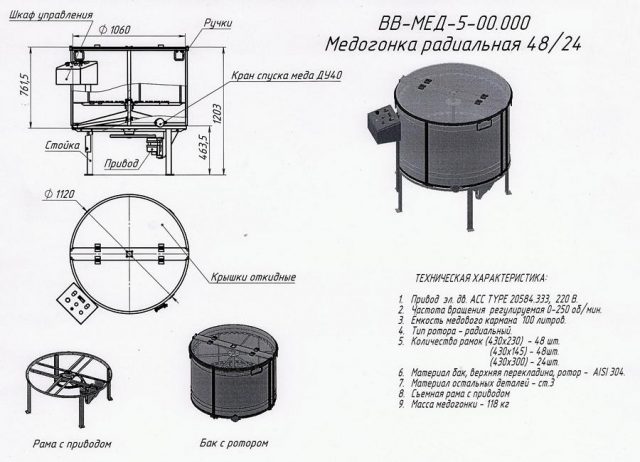

Radial honey extractor

The radial honey extractor has a number of advantages over other types of honey pumping machines:

Quantitative | Up to 700 half-frames can be centrifuged full time (when working with a helper) |

Qualitative | The honey is pumped out of the frames practically "dry" |

Marriage and breakdown | In the radial apparatus, the honeycomb is not deformed or jammed, and the number of broken honeycomb frames is no more than 1-13% |

Principal features of the radial honey extractor operation:

- The time of 1 honey pumping cycle varies from 10 to 25 minutes.

- 48 frame machine can process up to 100 honeycomb frames in 1 hour. Electrified honey extractor with speed control function - 145 frames.

- The volume of the pumped honey container is 185 liters.

- The radial apparatus can accommodate up to 50 small honeycomb frames (435x230 mm) and up to 20 oversized frames (435x300 mm).

- The automatic radial honey extractor is powered by a 0.4 kW motor with a main shaft rotation speed of 1450 rpm. Working voltage - 220 V.

- The rotation speed of the rotor axis of the apparatus ranges from 86 to 270 rpm.

Convenience, efficient use and simplicity of design make the radial honey extractor the most demanded device among beekeepers in Russia and abroad.

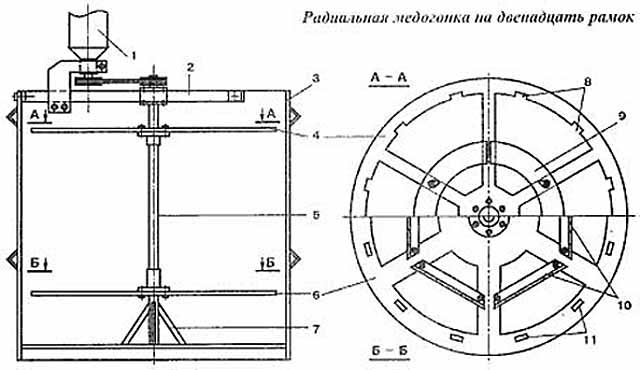

How a radial honey extractor works

The operation of the radial device is based on the action of centrifugal force, which arises from the rotation of the drum from a manual or electric drive. The printed frames are placed in the cassettes of the drum, which gradually unwinds and picks up speed. The centrifugal force begins to drown and push honey out of the combs, which splashes out onto the side walls of the tank and flows down to its bottom. From the tap located at the bottom of the honey extractor, the pumped out honey enters the container.

Diy radial honey extractor: drawings, assembly

A homemade honey extractor is a traditional design tank (barrel or vat) with a tapered bottom. A movable rotating rotor is installed inside it, which is fixed from below to the bottom of the tank, and from above to the crossbar. The rotor has lower and upper rings with fasteners for mounting cassettes or honeycomb frames. The rotary movement of the rotor is provided by a manual or electric drive, which is attached to the crossbar plate. For the outlet of the pumped out honey, there is a sleeve with a lid at the bottom of the tank.

Making a honey extractor yourself is not difficult if you follow the diagram above.

Disadvantages of a radial honey extractor

The disadvantages of the radial apparatus are as follows:

- large weight of the device, large dimensions;

- the presence of electrical wiring, dependence on the electrical network;

- relatively high cost.

These disadvantages of the device can be considered purely arbitrary, since honey extractors are already appearing from lighter materials, just as durable and inexpensive.

Wooden honey extractor

In a wooden manual honey extractor, all the parts are wooden, except for those that ensure the rotation of the frames. Outwardly, this device looks like a drum - the same flat, with a lowered sidewall. The entire mechanism of a horizontal shaft honey extractor is a rotating crossbar rotor, center axis and two bearings.

Such a device can be made from almost any wood, the main factor is that the tree does not need to be tarred and it must be dried. For a wooden mechanism, you can use pressed plywood, lining or solid wood, there is also a combination of materials.

The advantage of a wooden honey extractor is its light weight, compactness and ease of use. In addition, such a portable device is very easy to clean, disassemble or repair if necessary. Another important advantage of a wooden honey extractor is the process of honey pumping itself. Everything takes place under the complete control of the beekeeper, at an acceptable speed and with great efficiency, since the frames with honeycombs rotate in a horizontal plane and are processed on both sides.

Chordial honey extractor

Chordial 4-frame honey extractors with stainless steel reversible cassettes are used in small beekeeping farms with a small number of hives. The design of the apparatus involves the simultaneous pumping of honey from a small number of frames (2-4 frames). In the chordial device, the drum cassettes are located sideways to the wall of the tank body, along the chord.

Despite the fact that chordial honey extractors are actively used, this device can be considered an outdated model, since it has a number of significant technical shortcomings:

- During operation, the chordial device requires constant control of the beekeeper, therefore, an assistant is required to prepare the next batch of frames (printout).

- The rotor rotation cycle should be started with low revolutions so that the honeycomb does not break. Then the frames need to be turned over, the honey must be pumped out from the other side and again turned over to the starting position, to complete the started process.

- In the apparatus of the chordial type, the centrifugal force pressure is directed at right angles to the surface of the honeycomb, from which they are often deformed and pressed into the cassettes.

- In the chordial device, in addition to the drum itself, levers, cassettes and a drive move, which causes these mechanisms to wear out and break.

Chordial devices are flip-over (with movable cassettes) and non-revolving (with fixed cassettes). Their difference lies in the fact that in a honey extractor with flip-flop cassettes, the honeycomb frames can be simply “flipped” and there is no need to turn them over, but with non-reversible cassettes, the frames must be turned over and substituted on the other side.

Which honey extractor is better: radial or chordial

If we compare the radial and chordial honey extractors with each other, then we can identify a number of distinctive indicators that may indicate the advantages or disadvantages of the apparatus. Comparative characteristics showed:

- The radial device has twice the honey pumping capacity than the chordial model.

- During the pumping cycle, the radial honey extractor works independently, without inspection, and the beekeeper can use this time for other work. The chordial apparatus requires constant monitoring.

- In contrast to the chordial device, the radial device draws honey out of the frames almost completely.

- In a radial honey extractor, the frames do not break, because the main pressure during rotation is directed upward along the surface of the honeycomb, and not at an angle, as in the chordial one.

- It is much easier to remove the empty frames from the radial honey extractor as they do not stick to the drum during rotation. There is such a problem in the chordial apparatus.

- In a large radial honey extractor, it is possible to pump out the honey residues from the wax lids (beads) that have accumulated during the day. This cannot be done by working on a chordial apparatus with a lower load on the frames.

It should be noted that both the radial and the chordial apparatus have their admirers. It is possible that this is due to a number of conditions of a particular place, apiary and the requirements of the beekeeper.

DIY honey extractor from a washing machine

It is very easy to make a do-it-yourself honey extractor from an old washing machine, since the body of the device is ideal for this purpose. The advantages of such a rework are obvious - minimum costs, an almost finished stainless steel tank, the presence of electric drive parts.

It is possible to make a honey extractor from a washing machine as a radial or chordial apparatus. Installation of a manual or electric drive is possible - this is the choice of the beekeeper himself and his technical abilities.

Converting a washing machine into a honey extractor must be started from the tank. In the washer, the bottom is cut out and another tank is inserted into the body. The bottom of the future honey extractor should be in the form of a cone, on the very top of which a bearing is fixed. The rotor can be made from metal rods that need to be welded in the form of circles with a cross and a central tube (axis) between them.

On the lower and upper circle, hinges are welded for attaching the frames. If the honey extractor is planned to be of the chordial type, then cassettes are fixed to the circles with an arrangement along the chord of the circle. On top of the tank, a cross member with a plate and a bearing, on which the electric drive is mounted, is reinforced with large bolts.

DIY honey extractor from a plastic barrel

It is easy to make a honey extractor from a plastic barrel in just an hour. It can be called a "haste" beekeeper's handy tool. The advantages of such a device are obvious - the speed of assembly of the structure with a minimum of time and money.

But simplicity and low cost does not detract from its working properties. In fact, it is still the same convenient, efficient and working honey extractor, but a lightweight version.

To create a device from a plastic barrel, you will need the barrel itself (food), small pieces or scraps of an aluminum profile, a mesh, a metal rod, a nozzle for receiving pumped honey and any electrical appliance with a rotation function. Even a cordless screwdriver can be used for this purpose.

How to make a reversible two-cassette honey extractor with your own hands

The reversible two-cassette honey extractor has a number of advantages. Firstly, it is relatively small and is perfect for small apiaries and beginner amateur beekeepers. Secondly, all parts of this device are made of stainless steel, and this is a strong argument in favor of the durability of the device and great resistance to rust. Thirdly, the design of reversible cassettes allows you to quickly and efficiently pump out honey without turning the frame.

In addition, the magazine double-cassette revolving mechanism is equipped with a convenient aluminum crane, a cross-stand and, in the “electro” version, an electric drive of 12 V, 220 V.

The principle of operation of a reversible two-cassette honey extractor does not differ from the operation of a standard radial apparatus, but it has an essential and very useful feature. The fact is that the cassettes in this device have the ability to change and fix their position inside the drum using special rods. This makes it possible to pump out honey in different directions of rotation and, ultimately, more efficiently and completely collect honey from the comb.

Cassettes: buy or do it yourself

Honey extractor cassettes are used to hold honeycomb frames inside the drum of the apparatus. You can simply buy them at a specialized equipment store, but you can make your own. To make honey extractors, you will need a galvanized or chrome-plated mesh, aluminum rivets and a rivet wrench.

For homemade cassettes, stainless steel, an iron bar are used, and some beekeepers use pressed plywood, wooden blocks, galvanized or even ordinary wire to make cassettes.

The iron rod or mesh is assembled into a standard cassette structure according to the desired size, and then fastened with rivets, spot welding or thick wire. After that, if necessary, the finished cassette should be coated with a thin layer of paint for metal.

Do I need a stand

For ease of use, the honey extractor is placed on a special cross-stand. For professional beekeepers with a large production, the honey extractor is placed on a special stationary table.

The cross-stand in the optimal version should have a height of 37-40 cm from the floor level. In this case, you can safely install a standard enameled bucket under it, which greatly simplifies the task of collecting the pumped out honey.

Work rules

To get started, the honey extractor must be installed so that it does not wobble. It is installed on a flat floor surface, and the legs of the cross are screwed with bolts or self-tapping screws. Before printing the frames, they should be kept in a warm place for several hours so that the honey softens and begins to melt. Subsequently, this action will greatly simplify the pumping of honey in the drum of the device.

Bee frames are printed with a special knife or fork. For this purpose, use a special steam knife or slightly heat up an ordinary one. Unprinting frames with honeycombs must be done very carefully, guiding the knife strictly along the plane of the frame, not allowing the blade to go into the honeycomb. This work requires skill and continuity. If the honey extractor is small - from 2 to 4 frames, then one person will cope with the work. And if the device accommodates a larger number of honeycomb frames, then assistants will be required for such work.

After unsealing the frames, they are installed in cassettes, carefully distributing the weight throughout the drum. Before starting the centrifuge, you need to check the position of the frames again - the lower bars of the honeycomb frames should move forward. With the correct positioning of the frames, the drum of the honey extractor will smoothly pick up speed, and the wooden frames themselves will not break during rotation.

The rotation of the drum should be started gradually, smoothly accelerating it. First, one side of the combs is freed from honey, and then the frames are turned over with the other side and pumping from this side is completely performed. Then the frames are turned again and the process is completed.This action is necessary so that the pressure of the centrifugal force does not squeeze the honeycomb out of the frame, rendering them unusable.

If all the above actions are done correctly, then after a while the first honey will begin to flow from the lower sleeve of the honey extractor tank.

How to fit frames in a honey extractor

Before installing the frames in the drum, the honeycomb must first be printed. Then the frame is installed so that the bottom bar of the frame goes towards the rotation of the drum. This is important because the edges of the cell are always raised upward and skewing can occur.

When installing the frames, you need to ensure the correct distribution of weight in the drum. Cellular frames have different weights, therefore, frames of approximately the same size and weight should be placed in opposite sections. Otherwise, the drum will begin to wobble and will not be able to pick up the required rotation speed.

How can you wash a honey extractor

Over time, honey extractors need a thorough cleaning. Even stainless steel apparatuses begin to rust at the seams, in the joints of parts and oxidize. This not only spoils the appearance of the device. Aged drops of honey oxidize on wire cassettes and container walls and turn into black, poisonous mucus.

To prevent this from happening, every time after operation of the device, it must be rinsed and cleaned. This can be done as follows:

- If possible, remove the drive elements, covers and cross member from the honey extractor. Remove the cassettes and the shaft from the apparatus and place the tank sideways on the heating plate. This can be done in the summer kitchen. In doing so, care must be taken not to burn the rubber gaskets.

- Pour a little crushed wax into the container of the honey extractor. As soon as the wax begins to melt from heating, the tank must be turned over with care so that the entire inner side surface of the honey extractor is covered with a thin layer of wax.

- After the walls of the tank are covered with wax, the apparatus must be placed in an upright position so that the wax covers the bottom.

- Then, with a large swab made of rags, wound on a stick, you need to rub the side surfaces and the bottom so that, together with the wax, remove the remnants of honey, bee glue (propolis), rust and small debris.

- All small removable parts can also be washed and rubbed with hot wax.

The wax perfectly cleans the honey extractor from the products of honey processing, and this helps to keep the device in excellent working condition for many years.

How and how to lubricate a honey extractor

After an active season of collecting and pumping honey, the question arises of storing the honey extractor until next year. Before putting it on for the winter, you need to thoroughly rinse, dry and lubricate.

All surfaces, mechanisms, removable and static parts should be lubricated with anti-corrosion mixture and machine oil. Then pack the honey extractor under a special canvas cover to avoid debris, cobwebs, dust or small insects getting inside.

Store the honey extractor in a dry, ventilated room with a constant temperature. With the right mode and careful care, the device will last more than one season without repair and expensive maintenance.

Conclusion

A honey extractor is a necessary and very useful tool for the beekeeper. With its help, beekeepers can easily process all seasonal honey. Having shown a little ingenuity, this device can be made on your own. This does not require great engineering skills, but only improvised means, a set of the simplest tools and a desire to put hands on it.